Condenser Tapes

Unique product for most economic results: Coriatex fully meets technical and economic requirements of Modern Woollen Spinning Mills all over the world have long realized that only the best and most precise condenser tape is good enough to ensure material quality improvements of the entire output of a card which may easily amount to $50000 - 100000 annually. In today's keenly competitive markets mills specifying Coriatex Condenser Tapes with all their advantages will secure a decisive lead. For quality, there is no other Tape than Coriatex !

| Coriatex Standard | The original Condenser tape invented by LERIPA consists of top & bottom layers of double oak vegetable tanned full grain bovine leather of the highest grade with a special oriented polyamide core making it elastic but permanently stretch less. |

| Astra Chrome | Same as Coriatex but top & bottom layers of chrome leather. For price conscious customers. |

| Coriaweb | Similar to Coriatex except top & bottom of synthetic leather. This is ideal for use in humid and oily conditions. Has only one joint which is an advantage over leather, Very durable. |

| Coriaflex | 100% synthetic, long life, good web cutting, medium fiber adhesion. |

| Constant Tape Length | Owing to the molecular orientation of the plastic ply, Coriatex combines full elasticity with freedom from permanent stretch. |

| Constant Tape With | As the Coriatex Tape does not stretch in operation, there is no reduction of its original width. |

| Equal Tape Tension | The molecular-orientated plastic ply of the Coriatex Tape ideally ensures equal tension of all tapes in a Series set. Small variations in tape length which may result from deflection of the rollers of the tape condenser are easily taken up within the elasticity of the ORIATEX Tape. |

| Ideal Division of the Fibre | Constant tape width and uniform tension of all Coriatex Tapes guarantee precise division of the fibre web. Uniform roving means less ends down in spinning, higher yarn quality and a better product. |

| Optimum Web Contact | The full-grain leather or special polymer surface of Coriatex ensures optimum contact with the divided fibre web. The adhesion between leather and web will not be impaired even after long operation. |

| Down-time and Maintenance | As Coriatex Tapes always operate edge to edge with no stretch gaps forming between the tapes, the felting-up of rollers of the tape condenser is virtually eliminated. Coriatex thus helps to cut down-time and to increase the productivity of the card. |

| Tape Life | Owing to its elasticity without permanent stretch, its freedom from fatigue and its immunity to chemical attack, the plastic ply takes up full tape |

Ordering Specifications |

|

| Tape Length | Endless length corresponding to take-up device in centre position |

| Tape Width | Condenser groove Width. |

| Attention | Conventional tapes stretch in operation and keep growing narrower. For this reason it is customary to order such tapes slightly shorter and slightly wider than ultimately required. |

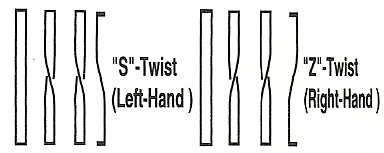

| Twist | “S’ (Left-hand Twist) or “Z” (Right-Hand Twist) as shown below. Therefore, Coriatex Tapes must never be ordered wider than groove width, or shorter than the tape length which corresponds to centre position of take-up roller. Coriatex Tapes, however, are not subject to stretch or loss in width in operation after having been installed at an initial  |

Good recognized brands of carding oil with neutral pH-value will never harm Coriatex. A high percentage of unsaturated elements (free fatty acids), however, could cause damage to the leather surface of the tapes.

All clearer rollers must be cleaned regularly (including rollers not easily accessible!). After changing carding oils, resin deposits may form on the tape surface because of interreaction of the two oils: in this case the tapes must be cleaned carefully by means of a scraper or the back of a knife. Coriatex Tapes never damage steel tape rollers or wear grooves in rubbers.

Thickness and Weight: Average thinkness is 3-3.3 mm (0.118”-0.130”), average weight is 3.13 kg/sq. meter (0.64 lbs/sq. ft.), average area of one set about 3 sq. meters (32 sq. ft.).

Width Tolerance +0 - 0.2 mm (+0' - 0.008'). At normal initial tension there is no loss in width.

The high standards of quality of Coriatex enable us to issue the following Letter of Guarantee:

1. Notwithstanding a far higher life, Coriatex Condenser Tapes are guaranteed to operate for at least 7,000 000 meters (7,650 000 yards), or two one-shift years.

2. After having been fitted at an initial tension of about 0.5 - 0.8% of their length Coriatex Condenser Tapes are guaranteed not to stretch in operation and, therefore, not to reduce in width.

Coriatex is protected by patents in the major textile countries. “Coriatex” is an internationally registered Trade Mark, Licencee productions have been established in a number of European & Asian countries and in the U.S.A.